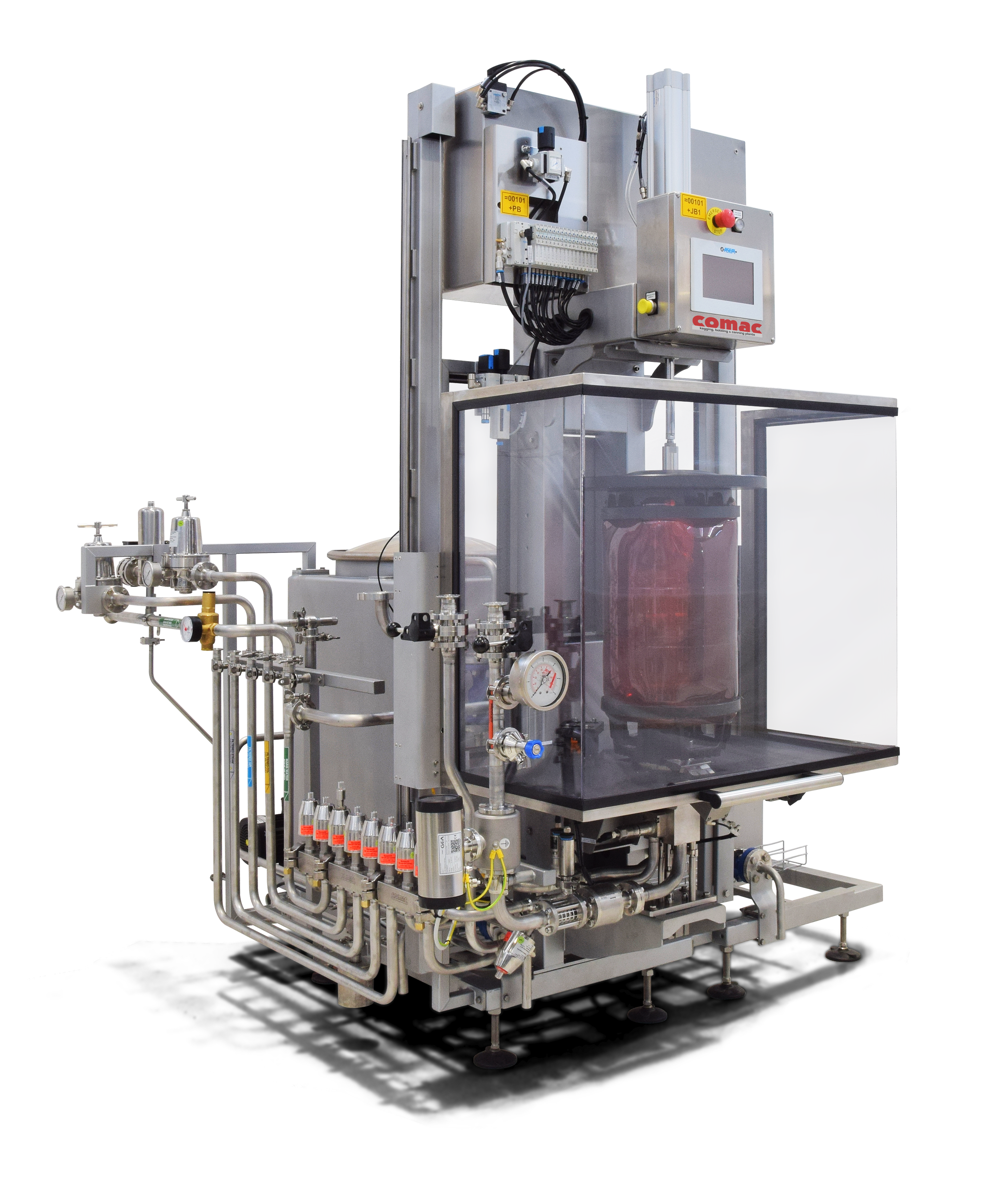

This line of semi-automatic keg washers/fillers has been designed and manufactured to offer a professional machine to small to medium companies as well. Smart kegging machines have the same filling head, washing head, process valves and monitoring instruments of bigger Comac plants. Suitable for use in beer, cider, soft drink, wine plants.

Basic model includes, factory-fitted, all that is necessary for a top-of-the-range standard machine.

Ideal for medium or low output

Output: 18 kph - 20 l - 1/6 bbl*; 16 kph - 30 l - 1/4 bbl*; 15 kph - 50 l - 1/2 bbl* (*The machine output depends on the keg cleaning times set in the HMI)

Dimensions: (LxWxH) 1,150 x 1,700 x 2,215 mm

Weight: 600 Kg

Loading deck: lowered

Ideal for medium or low output

Output: 36 kph - 20 l - 1/6 bbl*; 34 kph - 30 l - 1/4 bbl*; 32 kph - 50 l - 1/2 bbl* (*The machine output depends on the keg cleaning times set in the HMI)

Dimensions: (LxWxH) 1,750 x 1,700 x 2,215 mm

Weight: 800 Kg

Loading deck: lowered

A wide range of accessories is available: access the configurator to see those available for the model suitable for your production

K1 and K2 semi-automatic keg washers/fillers are equipped with the same washing and filling heads, process valves and monitoring instruments of bigger Comac plants, in order to ensure maximum quality and efficiency.

How much will you save, shipping within 4 weeks?

How much will you save, shipping within 4 weeks?

If you choose one from the Smart Kegging Machine Config, you will benefit from the guaranteed shipping within only 4 weeks - This means you will start production earlier.

In terms of turnover, you can figure out how much it would cost to anticipate the start of your production if you chose a Smart Kegging Machine instead of another competing product.

Select one Smart Kegging Machine - Based on your estimated output, delivery within 4 weeks allows you to have a production worth of $ XXXX

For over 30 years, Comac has been committed as a leader in the domain of kegging and bottling automated plants, installed in more than 100 countries around the world.

Since March 2021, we are part of the Canadian-based ATS Automation group: an addition to our international commitment.

Our kegging, bottling and canning plants guarantee maximum quality and attention for any specific customer requirement, from small, medium-sized craft breweries to the biggest structured companies.

Our conveyors are custom-designed to meet the specific requirements of the food & beverage industry, complying to current regulations.

We are able to manufacture conveyor belts of any type, shape and size, integrating them on existing lines when necessary, through a complete revamping.

For further enquiries please call (+39) 035 4994211 or write to [email protected] - Our team will be glad to answer all your requests.